Email: web@kota.sh.cn

Email: web@kota.sh.cn

Phone: +86 0510 83835888

Phone: +86 0510 83835888

In the modern industrial landscape, few materials manage to be as ubiquitous and strategically vital as electrodeposited copper foil. It is a foundational element that underpins both the digital revolution—serving as the conductive pathways in every printed circuit board (PCB)—and the global energy transition, acting as the primary current collector in next-generation Lithium battery equipment.

Driven by an unprecedented demand for electric vehicles (EVs), grid-scale energy storage, and high-speed communication technologies, the global market for electrodeposited copper foil is experiencing exponential growth. However, producing this material, which is thinner than a human hair yet strong enough to withstand industrial handling, is highly dependent on proprietary manufacturing expertise and, most critically, the precision engineering of the copper foil machine and the entire Copper foil production line. The quality, capacity, and efficiency of these machines directly dictate the performance and supply chain resilience of the entire new energy sector.

This report delves into the mechanics of how electrodeposited copper foil is made, why its characteristics are so vital, and the technological race among manufacturers to build the most sophisticated copper foil machine capable of meeting tomorrow’s performance demands.

The rise of ED copper foil from a commodity to a strategic asset is due to its unique combination of extreme thinness, high conductivity, and mechanical flexibility, making it irreplaceable in two key high-growth applications.

In lithium-ion cells used in EVs and energy storage, ED copper foil serves as the anode current collector. Its primary functions include:

Efficient Electron Transport: Due to copper's low electrical resistivity, it ensures minimal energy loss as electrons flow during charge and discharge cycles, directly impacting battery efficiency and thermal management.

The Ultra-Thinning Race: The industry is relentlessly pushing toward thinner foils, from 8 μm down to 6 μm, 4.5 μm, and even attempting 3.5 μm. Every micrometer reduction in the copper foil thickness translates into greater volume for active electrode materials (e.g., graphite or silicon), thus directly increasing the battery’s energy density and, subsequently, the EV’s driving range. This pursuit of ultra-thin foil makes the stability and precision of the copper foil machine a non-negotiable requirement.

Mechanical Resilience: The foil must endure hundreds or thousands of cycles of volume expansion and contraction as lithium ions intercalate and deintercalate into the anode material. This requires superior anti-fatigue properties and high tensile strength, which are controlled by the electrodeposition process.

In electronic devices, from smartphones to server farms, ED copper foil is laminated onto substrates to form PCBs. As data speeds increase (5G, AI, and cloud computing), the demands on the foil are evolving from simple conductivity to complex signal integrity:

Signal Integrity at High Frequency: The smooth and precise transmission of high-frequency signals is severely affected by the foil’s surface characteristics. Any roughness on the copper surface increases signal impedance and scattering, leading to signal loss (conductor loss) and crosstalk.

Adhesion without Compromise: The foil must adhere strongly to the organic resin or ceramic substrate, requiring a roughened surface, but this roughness must be minimized to preserve signal integrity. The Copper foil production line must therefore manage a critical trade-off between peel strength (adhesion) and conductor loss (smoothness).

The manufacturing of ED copper foil is a masterpiece of chemical engineering, precision mechanics, and electrical control, centered around the specialized copper foil machine. The process is continuous, running 24/7 to meet global demand, and is segmented into the electrodeposition stage and the subsequent surface treatment stage.

This is the core metallurgical process where the copper foil is born.

What is the Electrolysis Process?

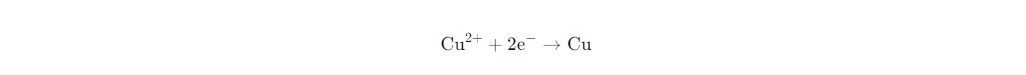

The process utilizes continuous electrolysis to reduce dissolved copper ions from a copper sulfate solution (the electrolyte) onto a rotating cathode surface using a controlled direct current. The chemical reaction at the cathode is:

The Central Role of the Cathode Titanium Drum: The copper foil machine is defined by its massive, high-speed cathode titanium drum. Titanium is chosen because of its exceptional inertness (corrosion resistance) and the fact that copper does not permanently bond to it. This non-stick characteristic allows the newly deposited, continuous copper sheet to be peeled off cleanly as the drum rotates. The drum's surface must be polished to a mirror-like smoothness to ensure the resulting copper foil has the necessary low roughness for high-frequency applications.

Control of Structure via Current Density and Additives: The quality of the ED copper foil—its strength, ductility, and roughness—is highly sensitive to process parameters:

Current Density: The rate at which the copper is deposited is controlled by the current density. Higher current densities increase production speed but can lead to a coarser, non-uniform crystalline structure, potentially reducing the foil's mechanical strength and uniformity. Precision control of the current across the entire wide surface of the drum is paramount.

Organic Additives (The Secret Sauce): The electrolyte contains meticulously chosen trace organic additives (such as glue, thiourea, or levelers). These chemicals adsorb onto the copper deposition front, inhibiting random crystal growth and encouraging the formation of ultra-fine, uniform grain structures. These additives are the primary mechanism for fine-tuning the foil’s mechanical properties and ensuring optimal surface smoothness.

After the “raw foil” is stripped from the drum, it proceeds through a complex series of plating and chemical baths to prepare it for bonding and protection. This is crucial for its function in Lithium battery equipment and PCBs.

Roughening Treatment (The Anchor): For one side of the foil (the "matted" side), a micro-scale electroplating process is applied to deposit tiny, dendritic copper particles (often referred to as "nodules" or "bumps"). This controlled roughness vastly increases the surface area and mechanical interlocking capability, critical for achieving the high peel strength required for lamination or electrode coating.

Densification and Passivation: The rough nodules are then locked in place with a thin layer of dense copper plating. Finally, a passivation layer (often involving zinc or chromium compounds) is applied. This layer significantly boosts the foil’s resistance to heat and oxidation, allowing it to survive the high temperatures encountered during PCB lamination or electrode drying in Lithium battery equipment manufacturing.

The single most critical variable controlled by the Copper foil production line, beyond thickness, is surface roughness (

In advanced electronics (operating above 1 GHz), the skin effect dominates, causing current flow to be concentrated near the surface of the copper conductor.

The Roughness Penalty: If the surface is rough, the actual path the high-frequency signal must travel is corrugated, making the effective path length longer than the geometric length. This increased path length leads directly to higher conductor loss (signal attenuation).

The Smooth Foil Demand: Consequently, for high-frequency applications, the demand is for Very Low Profile (VLP) or Ultra Low Profile (ULP) foil, which minimizes roughness to ensure smoother signal flow, lower transmission loss, and improved signal integrity. The copper foil machine must therefore produce an extremely smooth base foil that can only receive minimal roughening treatment necessary for adhesion.

In battery manufacturing, the requirements are dual-sided:

Adhesion (Roughened Side): The surface roughness ensures strong mechanical bonding between the copper current collector and the anode slurry (e.g., graphite or silicon). Without sufficient roughness, the anode material would delaminate during battery cycling or manufacturing stress, leading to capacity fade and failure.

Resistance (Smooth Side): The side facing the separator must be smooth to minimize potential internal short circuits and ensure uniform pressure distribution during winding/stacking.

The Copper foil production line must precisely engineer a differential roughness where the adhesion side is optimally textured while minimizing the impact on overall cell resistance and thickness.

The future of ED copper foil manufacturing is defined by three interconnected challenges that require deep collaboration between metallurgical science and mechanical engineering in the design of the next-generation copper foil machine.

Pushing the foil thickness below 4.5 μm introduces immense instability. A microscopic fluctuation in current density, temperature, or drum speed can instantly lead to pinholes, tears, or localized thickness variations. Next-generation copper foil machine technology is adopting:

Advanced APC Systems: Real-time, multi-point sensors and Artificial Intelligence (AI) enabled Automatic Process Control (APC) systems are needed to monitor and adjust critical parameters (current, temperature, additive concentrations) within microseconds to maintain perfect uniformity across large drum widths.

Enhanced Drum Precision: Titanium drums must be manufactured with near-perfect concentricity and surface flatness, requiring advanced dynamic balancing and polishing techniques to handle high-speed rotation without vibration that would disrupt the nascent copper layer.

As EV manufacturers increase battery lifespan and performance under rapid charging conditions, the demand for High-Strength, High-Elongation (HSHE) ED copper foil is growing.

The Trade-off: Historically, increasing strength often decreases elongation (ductility). HSHE foil requires both. Achieving this requires precise control over the copper crystal orientation (texture) and grain size during electrodeposition.

Innovation in Electrolyte Chemistry: This shift necessitates new additive packages and specialized electrolyte compositions to engineer the desired microstructures that maintain mechanical integrity while maximizing ductility—a core area of research and development within Copper foil production line manufacturers.

As copper usage scales, sustainability becomes critical. Future copper foil production line designs must focus on reducing energy consumption and material waste:

Energy Efficiency: The electrolysis process is highly energy-intensive. Innovations like higher current efficiency and reduced ohmic losses in the copper foil machine design are essential to lower the overall carbon footprint of Lithium battery equipment production.

Waste Reduction: Reducing pinholes and tears in ultra-thin foil production minimizes scrap and maximizes material utilization, improving cost competitiveness and environmental impact.

The copper foil machine is no longer just a piece of equipment; it is a complex chemical reactor and precision mechanical system that sits at the nexus of the future energy and information economies. The race to master this technology defines the global competitiveness in the most strategic sectors of the 21st century.