Email: web@kota.sh.cn

Email: web@kota.sh.cn

Phone: +86 0510 83835888

Phone: +86 0510 83835888

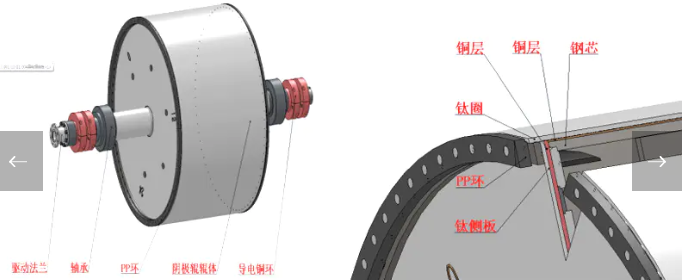

Basic concept of cathode rollers

Cathode rollers, as the name implies, are core equipment used in the production of electrolytic copper foil. It mainly deposits the copper layer evenly on the surface of the titanium roller through electrodeposition technology to form high-quality electrolytic copper foil. Electrolytic copper foil is widely used in lithium batteries, integrated circuits, touch screens and other fields, especially in the new energy vehicle industry. The performance of the battery is directly related to the endurance, charging efficiency and service life of the whole vehicle.

The important role of cathode rollers in the production of electrolytic copper foil

Core equipment in the electrolysis process: The working principle of the cathode roller is based on electrodeposition technology, that is, the copper ions are reduced from the electrolyte and deposited on the surface of the titanium roller through the action of current in the electrolytic cell. In this process, the cathode roller plays the role of a current conductor and a carrier of copper deposits. The surface of the titanium roller is finely processed to ensure the uniformity and stability of the electrolytic copper foil.

Key factors determining the quality of electrolytic copper foil: The quality of the cathode roller directly affects the thickness uniformity, surface finish and mechanical strength of the electrolytic copper foil. The production process of electrolytic copper foil is very complicated and involves multiple links. If there are defects on the surface of the cathode roller, the surface of the copper foil will be uneven, affecting the electrical properties of the copper foil, and then affecting the performance of the lithium battery. In order to ensure the high-quality production of electrolytic copper foil, the material, processing technology and surface treatment of the cathode roller are crucial.

Design and manufacturing process of cathode roller

Material selection and processing: The material of the cathode roller is usually titanium alloy. Titanium has excellent conductivity and corrosion resistance, and is an ideal material for producing high-quality electrolytic copper foil. During the manufacturing process, the surface of the titanium roller is specially treated to ensure uniform deposition of the copper layer. Common treatment processes include surface spraying, pickling and high-temperature oxidation, which can not only improve the surface quality of the titanium roller, but also enhance its durability.

Precision manufacturing technology: The precision of the cathode roller directly affects the quality of the electrolytic copper foil, so highly precise technical support is required during the manufacturing process. With the development of science and technology, the application of automated production lines and CNC equipment has greatly improved the processing accuracy of the cathode roller. By using advanced CNC technology, the size, shape and surface quality of the cathode roller can be ensured to meet the best standards.

Surface treatment technology: The smoothness and uniformity of the cathode roller surface are important factors in ensuring the quality of electrolytic copper foil. In order to ensure the smooth surface and uniform thickness of the copper foil, the surface of the cathode roller needs to be finely treated. Common surface treatment methods include chrome plating, spraying and surface polishing. Through these treatments, the cathode roller can not only improve the uniformity of copper deposition, but also effectively reduce the defects on the surface of the copper foil.

Improvement of the production efficiency of electrolytic copper foil by cathode roller

Improving electrolysis efficiency: The cathode roller effectively improves the production efficiency of electrolytic copper foil through a uniform electrodeposition process. In traditional electrolytic cells, the reduction deposition of copper ions is a slow process. By optimizing the design of the cathode roller, the current distribution in the electrolytic cell becomes more uniform, and the copper layer deposition rate is improved, thereby improving production efficiency.

Extending the service life of equipment: The excellent design of the cathode roller not only ensures the high-quality production of copper foil, but also effectively extends the service life of the equipment. By adopting highly corrosion-resistant titanium alloy materials and precise surface treatment technology, the cathode roller can resist chemical corrosion and wear during long-term electrolysis, greatly reducing equipment maintenance costs and equipment downtime.

Reduce production costs: With the continuous optimization of cathode roller technology, its stability and durability have been improved, and the loss in the production process has been greatly reduced, further reducing production costs. At the same time, as the quality of copper foil is guaranteed, the product qualification rate and shipment volume have also been improved, further reducing unit costs.