Email: web@kota.sh.cn

Email: web@kota.sh.cn

Phone: +86 0510 83835888

Phone: +86 0510 83835888

The operation of a copper foil slitting machine is based on a highly integrated mechanical and automated system. Its working principle can be divided into three core steps: tension control, guide system, and knife cutting. Each step provides a solid guarantee for the precision and stability of the final product.

Step 1: Tension Control to Ensure Stable Feeding

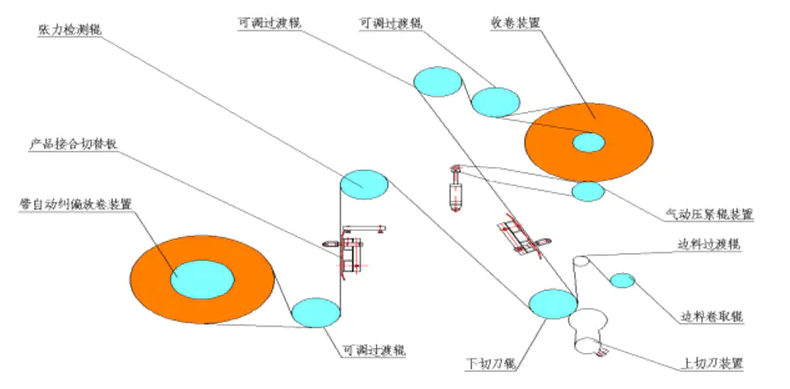

The first step in slitting begins with the feeding of the copper foil. During this step, the equipment applies appropriate tension to the copper foil roll via a tension roller system located at the feed end. This tension control does not simply tighten the material; rather, it uses a tension feedback system to monitor and adjust the tension state of the copper foil in real time.

Excessive tension can easily cause wrinkling or stacking of the copper foil during the slitting process, while excessive tension can cause the material to stretch and deform, affecting dimensional accuracy. High-performance copper foil slitter machines utilize a coordinated control system with servo motors and tension sensors to ensure constant, appropriate tension during the feeding process, ensuring stability and efficiency of subsequent processes from the source.

Step 2: Guide System Maintains Foil Flatness

After tension control is completed, the copper foil is guided into the guide system, which precisely transports the foil to the cutting area. The guide system, consisting of photoelectric sensors, a guide mechanism, and a guide rail structure, automatically detects the foil's edge position and makes fine adjustments to prevent material deviation.

Throughout the cutting process, the copper foil must maintain high flatness and center alignment. Any slight deviation can result in uneven width or rough edges in the finished product. The guide system's automatic guide capability significantly improves cutting accuracy and efficiency, reducing scrap rates and is a key technical step in the entire slitting process.

Step 3: Knife Group Cutting for Precise Slitting

After guiding and positioning, the copper foil enters the core cutting unit—the knife group cutting area. This area typically uses a combination of circular or straight knives, allowing flexible adjustment of knife positions based on product specifications. The knives are primarily made of high-strength alloy steel and precision-ground to ensure a smooth, burr-free cut.

The operator can preset the cutting width and number of knife groups through the control system, enabling simultaneous slitting of multiple strips of copper foil. Some high-end models also support automatic tool change and tool position memory, significantly reducing adjustment time and increasing production flexibility. Automatic chip removal and dust collection systems keep the cutting area clean, effectively extending tool life and ensuring a stable production environment.

In addition to the three main steps mentioned above, the copper foil slitting machine is also equipped with a reel system for uniformly rewinding the slit copper foil strips. A high-quality reel tension control system prevents loose, uneven, or wrinkled copper foil, ensuring the final product is tightly wound and has a neat appearance.

Intelligent Upgrades Drive High-Precision Manufacturing: The Core Application Value of Copper Foil Slitting Machines in Various Industries

Modern copper foil slitting machines have not only continuously optimized their mechanical structure but also made significant progress in intelligent control. Many machines are equipped with PLC control systems, touch-screen human-machine interfaces (HMIs), and remote monitoring and alarm systems, allowing users to monitor equipment operating status, production statistics, and fault information in real time.

Some advanced equipment even integrates machine vision and AI algorithms to detect and identify surface defects in copper foil, ensuring that every batch of products meets quality standards. Furthermore, the equipment's data networking capabilities enable production information to be uploaded to the MES system, enabling digital management of the manufacturing process.

Copper foil slitting machines are widely used in a variety of processes, including lithium battery copper foil manufacturing, circuit board material slitting, and flexible electronic substrate processing. For example, in the new energy vehicle industry, high-performance lithium batteries require extremely stringent copper foil thickness tolerances. The introduction of a high-precision slitting machine can significantly improve product qualification rates and production line efficiency.

In fields such as 5G communications and consumer electronics, ultra-thin copper foil and ultra-narrow widths have become mainstream trends, placing higher demands on slitting machines. The continuously upgraded copper foil slitting machines, with their superior technical performance, are helping companies seize opportunities in the fiercely competitive market.